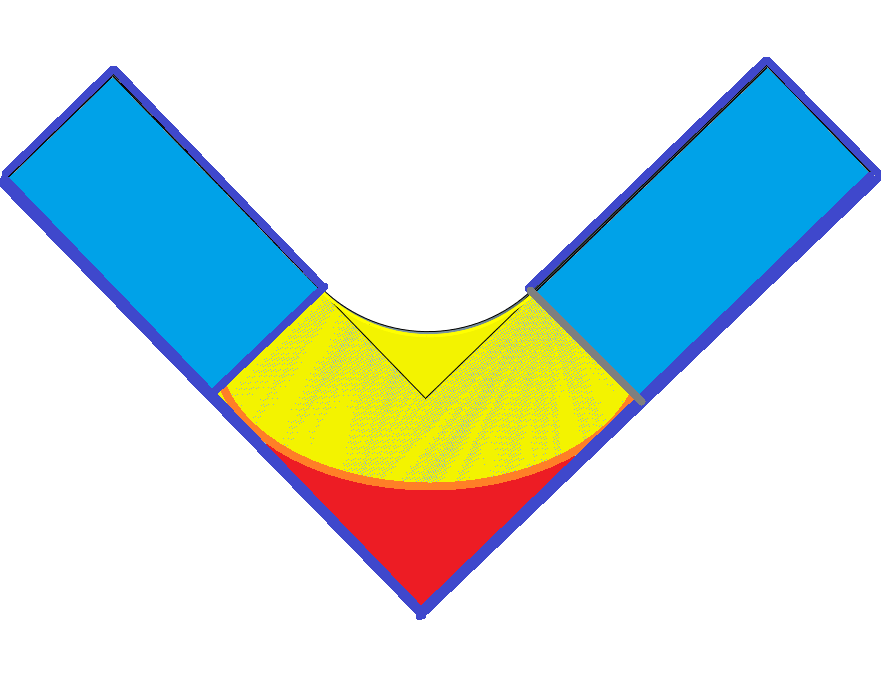

Single joint: it creates one joint i the centre of the selected face;

Multiple joints: it creates more joints on the selected face. User must type in also the number of joints and the distance of the first one from the selected edge;

Multiple equidistant joints: this works as the previous one, but joints will be automatically distribuited in an equidistant pattern along the whole edge;

Multiple equidistant joint with distances: this works as the previous one, but user can choose to have a certain distance from the starting edge and the arriving edge

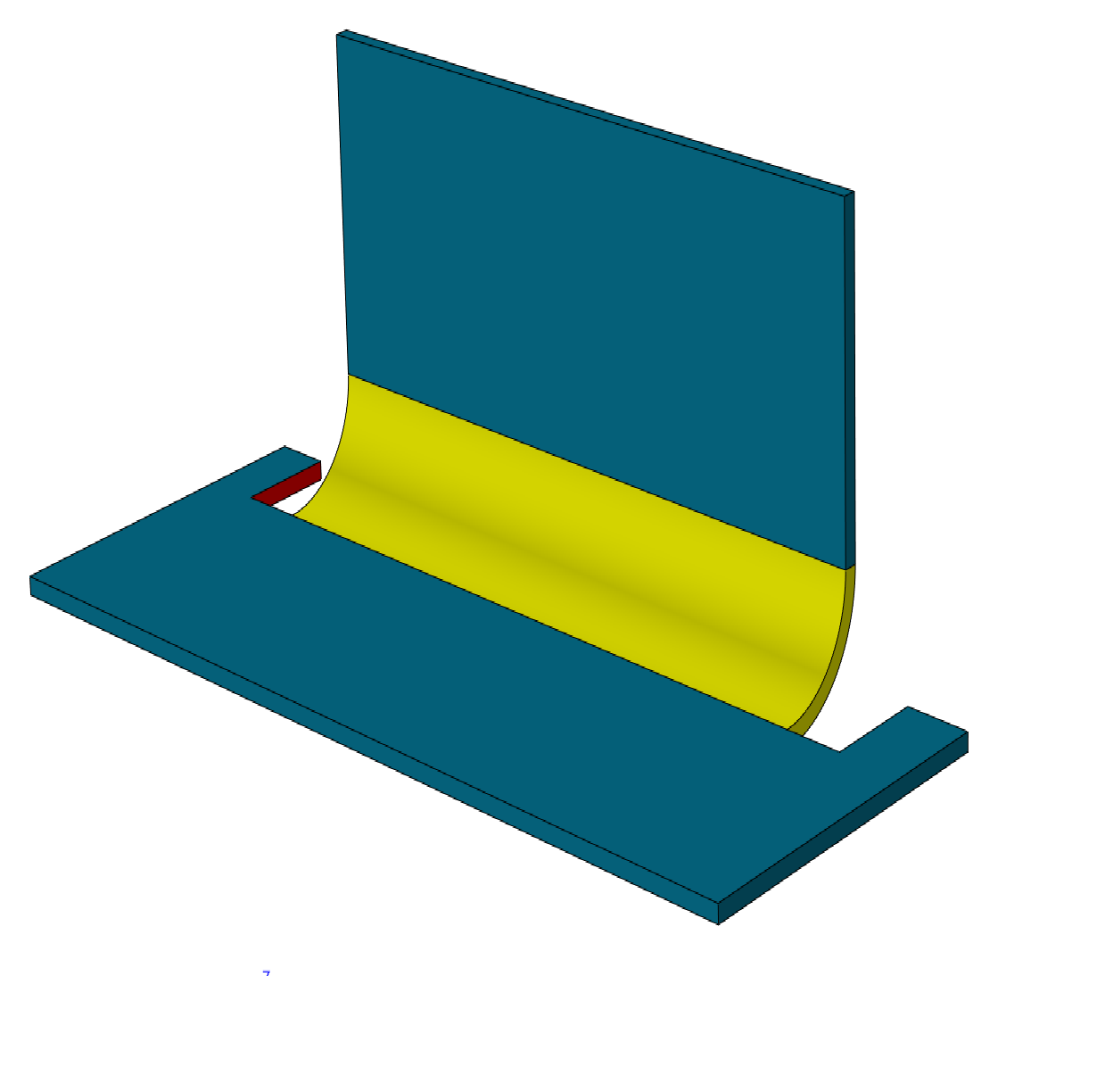

single centred slot: set the width of the slot and the dimension of the portion of material you want to keep;

multiple slot: set the width, the number of slots and their length.

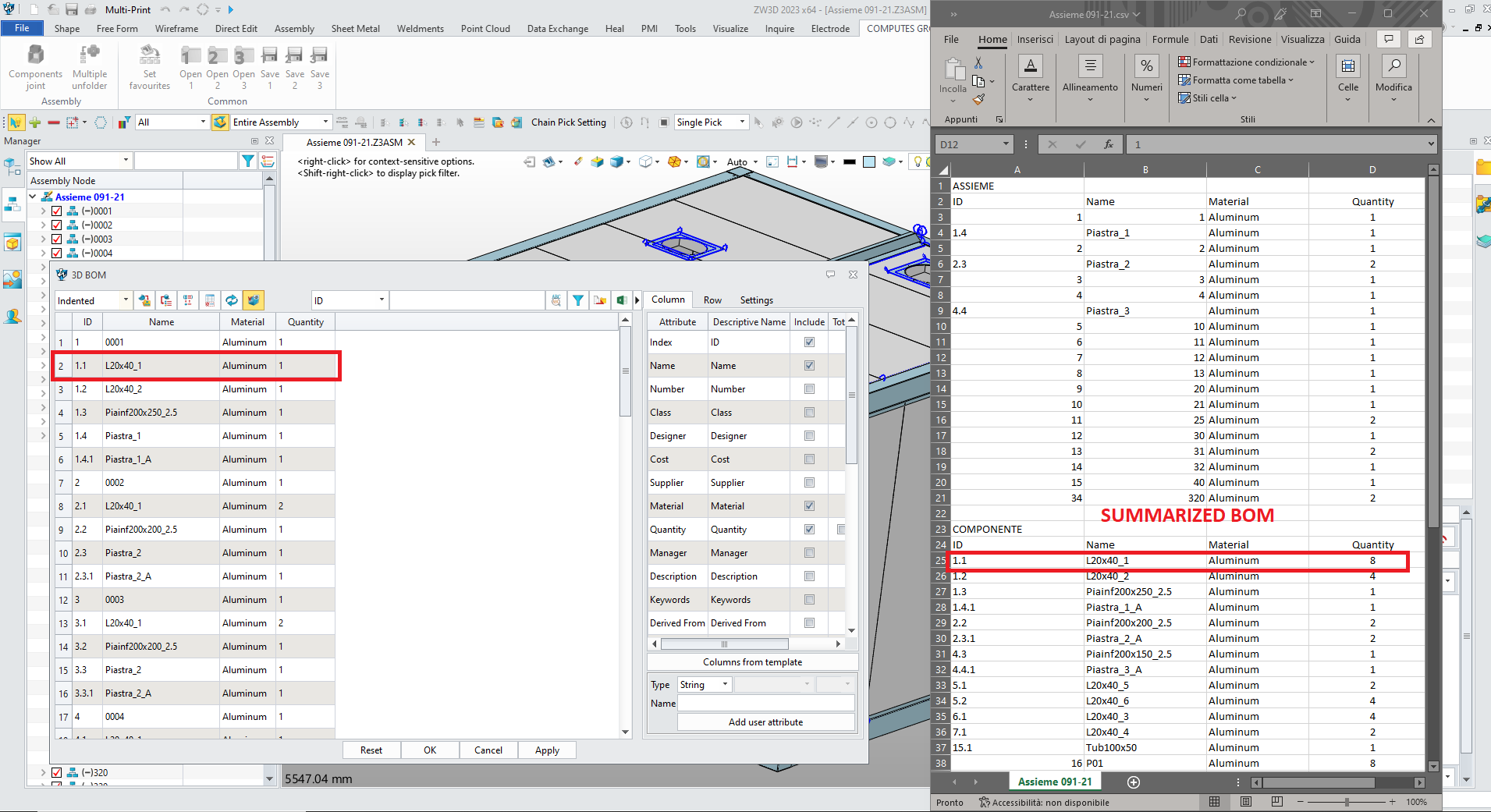

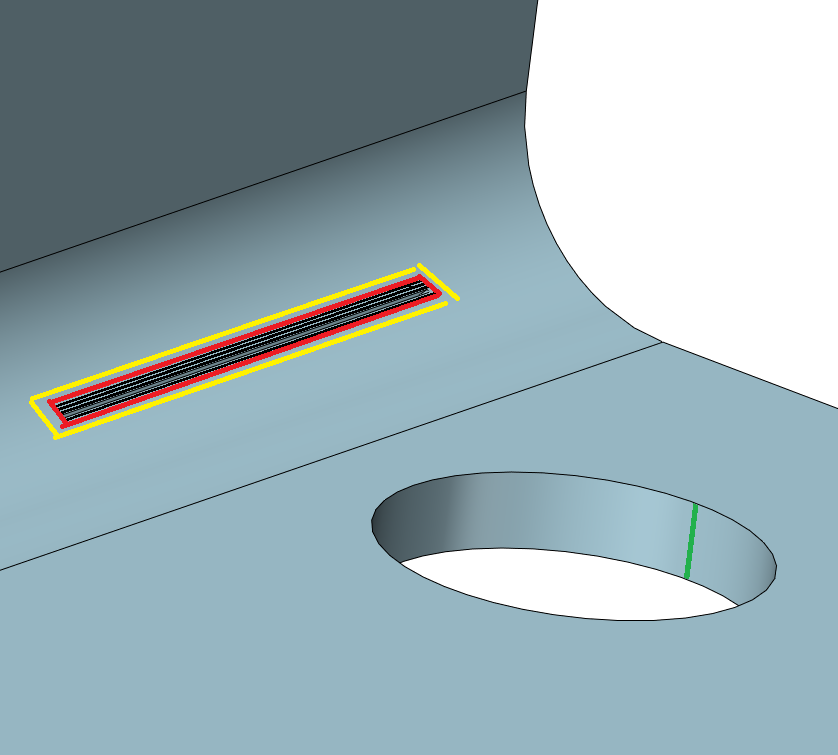

Flat pattern view with bend datas;

Flat pattern view without bend datas;

3 standard view + ISO view + flat pattern view with bend datas and the flat pattern view without data in a second sheet (as AUTO SHEET DRAWING macro);

Flat view of a plate

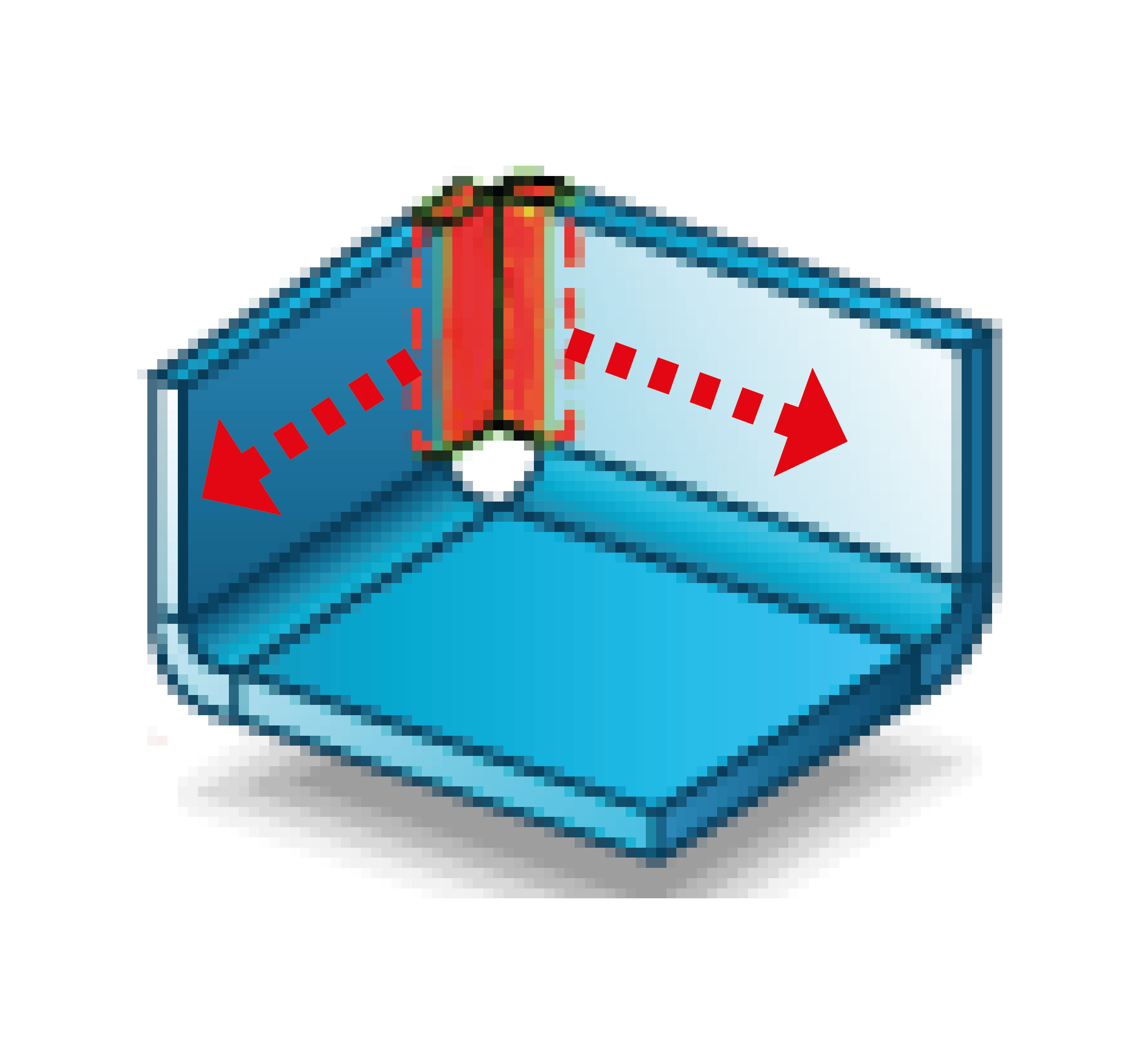

Set a certain material and detect the thickness of the part;

Save directly the DXF file in a specified folder;

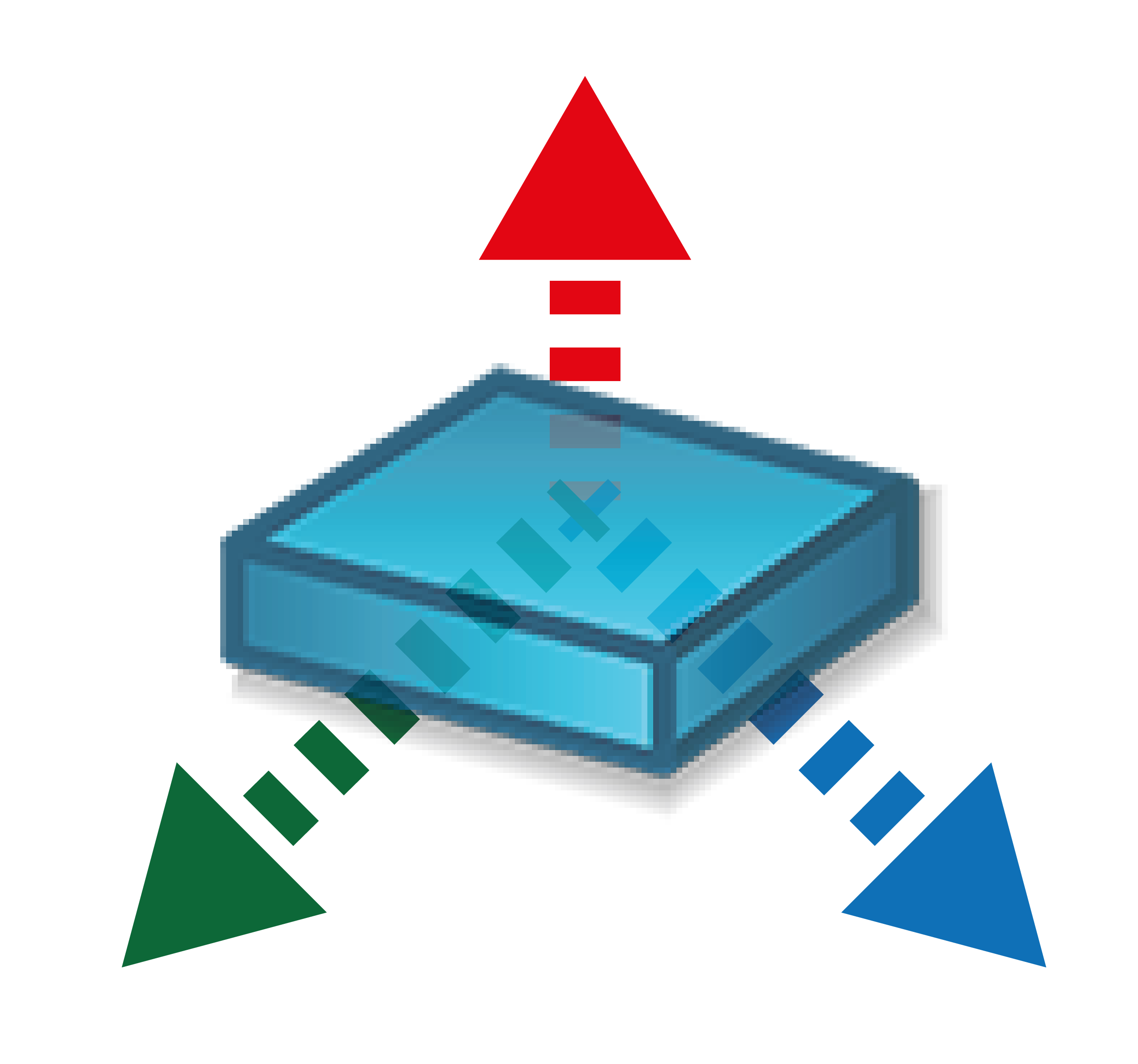

Create a CSV report containing information about the parts in the assembly (code, material, thickness, quantity, DXF path…). This file will be useful to have a report of what I did but it can be imported for example in a CAM application.